2025 SUPERFLOW Titanium Powder

Titanium Powder

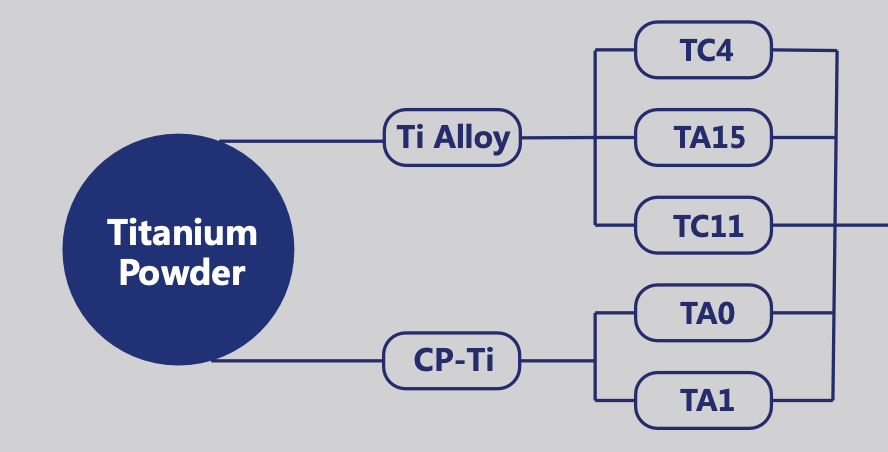

Titanium powder comes in Ti Alloys (TC4, TA15, TC11) and CP-Ti (TA0, TA1), available in particle sizes for MIM/Binder-Jet (0–20um/0-40μm), SLM (15–70μm), and EBM/HIP (45–150μm). Precision-engineered for aerospace, medical, and industrial applications—ready to shape the future.

Titanium Feedback

Titanium feedstock is available in Ti Alloys (TC4, TA15) and CP-Ti (TA2), with custom OSF ranges from 1.16 to 1.21. JSJW tailors feedstock to meet each customer's specific requirements for precision and performance.

Engineered for Performance. Trusted for Precision.

-

High Quality

Manufactured with strict quality control to ensure consistency across every batch.

-

Excellent Sphericity

Uniform spherical shape enhances flowability and packing density in additive processes.

-

High Purity

Low oxygen and impurity levels make it ideal for high-performance applications.

-

Ultra-Low Hollow Ball Content

Reduces defects and boosts final product strength and reliability.

FAQs

What is the maximum production capacity of JSJW’s titanium powder facility?

JSJW’s facility has a maximum production capacity of 800 tons per year, ensuring scalability for large-volume orders.

What is JSJW’s IPCA technology?

IPCA stands for Induction heating and Plasma melting Combined Atomization. It’s JSJW’s advanced production method for producing high-quality titanium powder with superior sphericity and purity. The IPCA process boasts a nearly 100% yield rate, maximizing material efficiency and minimizing waste.

TWhat makes JSJW’s spherical metal powders ideal for aerospace and medical applications?

JSJW powders are produced using advanced Plasma Atomization technology, ensuring high purity, excellent sphericity, and consistent flowability—critical for precision in additive manufacturing (AM). Backed by AS9100D and ISO13485 certifications, our powders meet the rigorous standards of the aerospace and medical industries.

Can JSJW customize powders for specific manufacturing needs?

Yes, we offer customized metal and alloy powders based on Titanium (Ti), Nickel (Ni), Iron (Fe), Cobalt (Co), Tungsten (W), and Molybdenum (Mo). Each formulation is tailored to meet your exact material and performance requirements.